The electrostatic process was designed to meet your refinishing needs without overspray or fog. We use this process on all of the appliances and metallic objects we refinish.

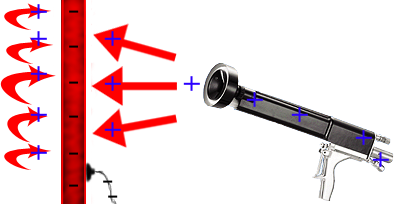

Instead of blowing the coating on with 60 pounds of air pressure, the coating is applied to the item through a round revolving nozzle, spinning at approximately 600 R.P.M. We atomize the paint with a positive electrical charge, and the item to be refinished is given a negative charge. Then the coating is attracted to the metal item like metal shavings to a magnet -- giving a smooth, even coat of paint to even the most hard-to-reach places.

For information about the quality of our paint and drying times, we use Urethane Paint, for well venthilated areas and outdoors. If the item is painted, indoors with little venthilation, an Enamel Paint is used, in accordance with federal regulations.